- Products

- Service

- Project Business

- References

- fischer group

- Contact

- Home

- Project Business

- Tunnel

- Anforderung Tunnel

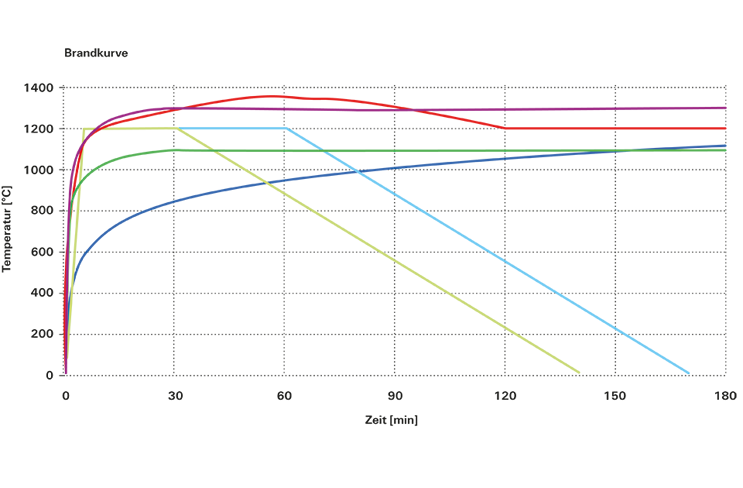

Unfortunately, you can never completely rule out the risk of fire in a tunnel installation. However, preventive structural fire protection measures are absolutely necessary to keep the risk of personal injury and material damage as low as possible. These are based on extensive calculations and tests on the fire course and fire temperature. The fischer range consists of a large number of anchors that have been subjected to a fire test in accordance with special fire curves (DIN 4102, RABT/ZTV, Rijkswaterstaat curve).

Of course, fischer also offers various systems for increased anchoring depths. In fact, there are different tunnel fire curves, and it depends on the country and the standard used for the tunnel project. The RAB/ZTV tunnel curve (Germany) rises to 1,200°C within 5 minutes. Anchors approved for the RAB/ZTV curve are FAZ II, FHB II and FHB dyn, M16 in material 1.4529.

With an even higher temperature load, the Rijkswaterstaat (Netherlands) tunnel fire curve tests the systems with their fasteners. For this fire curve with a maximum temperature of 1,350 °C, fire protection panels and spray systems are tested with FNAII in a realistic test. The last known tunnel fire curve is the hydrocarbon curve.

This curve is based on the assumption of a damage fire with flammable liquids, e.g. gasoline, chemicals, etc. at 1,100 °C over a very long period of time. In some areas of a tunnel project that are not affected by the traffic itself, other fire curves can be crucial. In Germany, for example, the unit temperature time curve (ETC), which is based on the German standards DIN 4102 and ISO 834. For applications that correspond to this type of fire curve, the fischer range offers a wide selection of products.