- Products

- Service

- Project Business

- References

- fischer group

- Contact

- Home

- Project Business

- Sanitary Heating Air Conditioning Ventilation

- Fixed point sliding elements

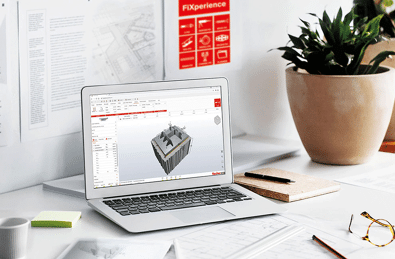

Maximum flexibility anytime, anywhere!

With the fischer fixed points and sliding elements, planners and installers effectively prevent pipe systems from being damaged by temperature fluctuations. Different designs cover different loads and structural conditions. Significant movements can occur due to thermal expansion of hot lines or contraction of cold lines. The correct use of fixed points and sliding elements effectively prevents damage to the cable attachment and the structure. The design of large-scale installations with high loads is also possible through product solutions for the different load levels. .

This gives us 55% time savings in our drilling operations

The fischer FAZ II bolt anchor is the steel anchor for the highest demands (incl. approval for seismics). The steel anchor can be used to secure heavy loads in cracked concrete