The fire protection test reports meet the requirements for fire protection in accordance with the building legislation of the countries and, especially for Germany, in accordance with the nationally identical Pipeline Directive (LAR) based on the Model Pipeline Directive 2015 (MLAR 2015). Personal protection is specified in the ML AR by clear regulations for escape routes such as corridors, stairwells, corridors between stairwells and the exit to the open air. The key message is to ensure the safety of escape routes by ensuring the function of the fire protection ceiling.

Compliance with the minimum distance min a ≤ 50 mm according to MLAR 2005 between installations and the suspended fire protection ceiling F30 below (fire resistance duration oF30 minutes) is required. Based on the fire tests, load specifications were determined for a fire resistance period of 30 minutes in relation to the maximum permissible deformation of, for example, mounting rails or pipe clamps. The necessity of these considerations results from the properties of the steel, which is subjected to a temperature of > 800 °C at 30 minutes according to the unit temperature curve. In addition, the same specifications for a fire resistance period of R30, R60, R90 and R120 according to EN 1363-1 or F30, F60 , F90 and F120 according to DIN 4102-2 are documented in the test reports.

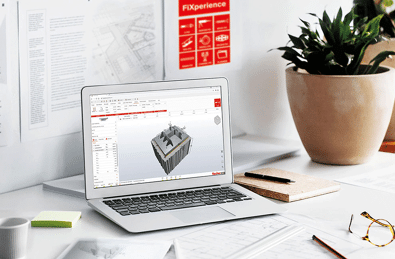

You also get the best expert advice for your project!

In existing expert opinions from fischer, load specifications were determined analogous to the MLAR for a fire resistance duration of 30 minutes in relation to the maximum permissible deformation of, for example, mounting rails or pipe clamps. The necessity of these considerations results from the properties of the steel, which is subjected to a temperature of > 800 °C at 30 minutes according to the unit temperature curve. In addition, the thinner-walled mounting rails compared to normal steel profiles are subject to greater deformation, which is why corresponding fire tests served as the basis for the expert opinions of fischer, and not calculations according to DIN EN 1993-1-2 (Eurocode 3).

Eurocode 3 has been issued for the dimensioning of steel structures, in particular for the dimensioning of supporting structures in the event of fire. In the structural design for steel structures, thick-walled steel components are usually used whose material thickness is many times thicker than the mounting rails used for pipe systems or pipe support systems. The failure characteristics and resistance to fire of thin-walled mounting rails differ significantly from those of thick-walled steel components.

Fire-resistant pipe fastening is to be created with a few components from the FUS fischer universal rail system as well as the two-screw pipe clamps. The specifications in the expert opinions are clearly specified with regard to the possible applications as well as the design of the connection solutions and must be taken into account during assembly.

Based on the determined fastening reason, the fastening materials (usually steel or chemical fastening materials) with a corresponding fire certificate can then be selected.

The required FUS mounting rails are suspended using the design elements and accessories specified in. Suspension is carried out by means of threaded rods or mounting rails, taking into account the connection to the substrate.

This gives us 55% time savings in our drilling operations

The concrete screw head fits geometrically perfectly into the FUS rail system

The scaling simplifies cutting to length and positioning of the fasteners.

The adjusting nut as a connection nut enables easy, subsequent height adjustment