The basic principle of ventilated rainscreen façades relies on subframe systems to transfer loads from the façade to the underlying subconstruction of a building.

These systems typically consist of

Depending on the project requirements the systems can be adapted to provide e.g. concealed fixing, reduction of heat bridges or special solutions for various materials.

The most economical way of fixing cladding materials to ventilated rainscreen façades is the exposed fixing.

For exposed and direct fixed façades fischer offers various systems, which mainly consist of vertical subframe elements only. Components of the vertical level are wall holders and vertical profiles as well as necessary connectors and fixings. Additionally, various solutions for direct fixed façade panels are part of the systems, e.g. rivets, self-tapping screws or clamp solutions.

The exposed systems are defined by their visible fixing points at the front side of the façade, caused by e.g. rivets or clamps.

Even though this system is less visibly appealing, it has the huge advantage of short installation times due to the simplicity of the system. This point on one hand and material savings on the other hand enable this system to be very cost efficient.

Advantages of exposed façade systems:

Exposed fixing solution for lighter cladding materials or smaller façade panel sizes.

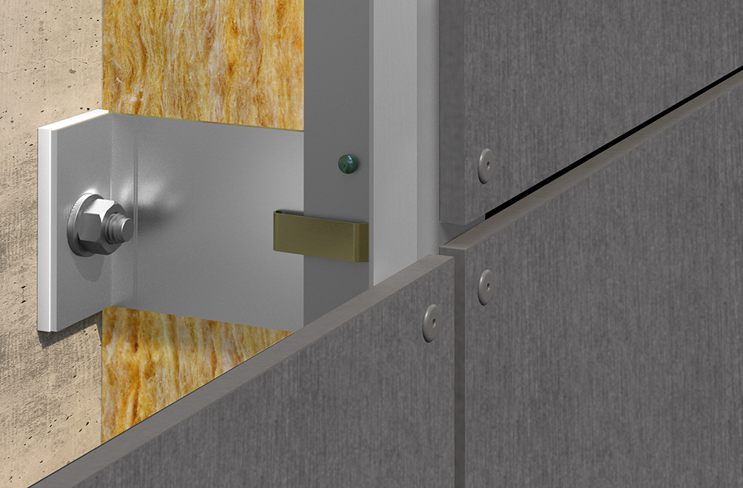

The ATK 100 is the subframe system for exposed fixing of façade panels with rivets or screws.

The system typically consists of wall holders, vertical profiles, connection elements and fixings.Several wall holder options are available, offering the most suitable solution for individual project requirements regarding load performances and thermal efficiency. Besides the standard aluminum L-wall holder FLH there are the thermally optimized products ZeLa, ZeLa Click and stainless steel bracket FLH R as well as the refurbishment specialist ATK 601. The wall holders are anchored to the building substrate using fischer fixings such as bolt anchor FAZ II or frame fixing SXRL.

The system also includes the vertical profiles to transfer the loads. Those are connected to the wall holders using special rivets or self-drilling screws. As with the wall holders, there are different geometries and sizes available for the vertical profiles.

Rivets or screws, available from the supplier of the cladding material, can be used to fix the façade panels to the vertical profiles. To make the façade more visually appealing, the rivets can be coated in the respective panel color.

Typical façade panel materials for this kind of system are fiber cement, HPL or ACM.

The ATK 100 system can also be used as a base system for other systems, such as ATK 100 KL or ATK 103.

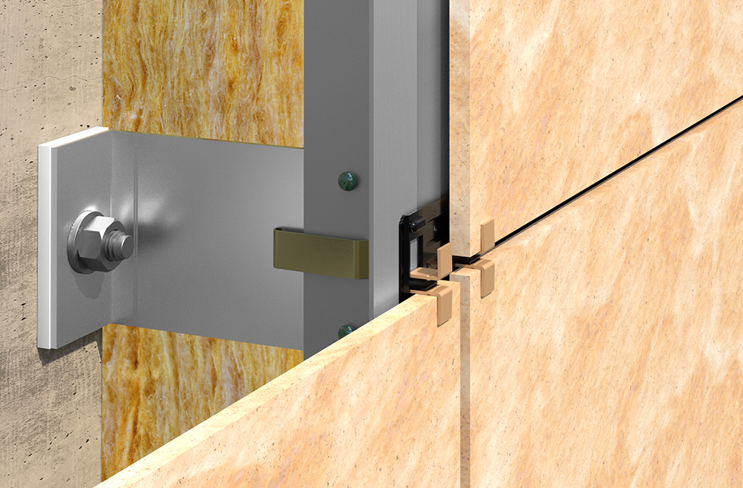

Clamp solution for exposed fixing of lighter cladding materials or smaller facade panel sizes.

The ATK 100 KL is the system for exposed fixing using special façade clamps. It is based on the ATK 100 subframe system consisting of wall holders and vertical profiles. Additionally, the clamp elements are mounted on the vertical profiles and keep the panels in place. For each section of the façade (e.g. joint or embrasure) there are suitable types of clamps available. The clamps are also adapted to the different cladding material thicknesses.

For a more appealing visual of the façade, the clamps can be coated in respective panel color to make them less visible.

Typical façade panel materials for this kind of system are ceramic tiles, fiber cement or HPL.

Clamp solution for exposed fixing of facade panels as well as concealed fixing of terracotta panels.

ATK 102 is the system for exposed fixing using special façade clamps. It is based on the ATK 100 wall holders and an ATK 102 vertical profile, which is specially formed to insert and install ATK 102 clamps to fix façade panels. Here, the façade panels are fixed visibly at the edge of the panel. For slotted materials, e.g. special terracotta, the clamps can also be mounted concealed in the panel joints.

There are different variants of the clamps for the various applications (e.g. joint, embrasure) as well as for different cladding materials.

Typical façade panel materials for this kind of system are ceramic tiles, fiber cement or HPL.