- Products

- Service

- Expertise

- References

- fischer group

- Contact

- Home

- Expertise

- Façade systems

- Concealed fixing - undercut

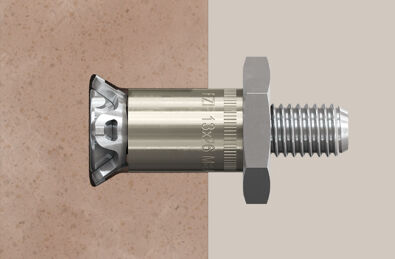

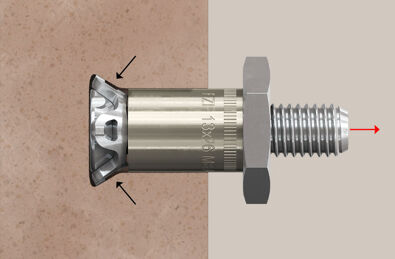

The fischer undercut anchors FZP II enable the concealed fixing of façade panels in ventilated rainscreen façades. It opens up the way for the design of advanced, complex façades - and all this in an easy and economic way. The reason lies in the system itself - FZP II, the fischer Zykon Panel Anchor, which is an undercut anchor and therefore ensures a inter-locking and completely stress-free fixing in an pre-drilled conical and undercuted drill hole. Internal reaction forces between anchor and material result not before the impact of external forces.

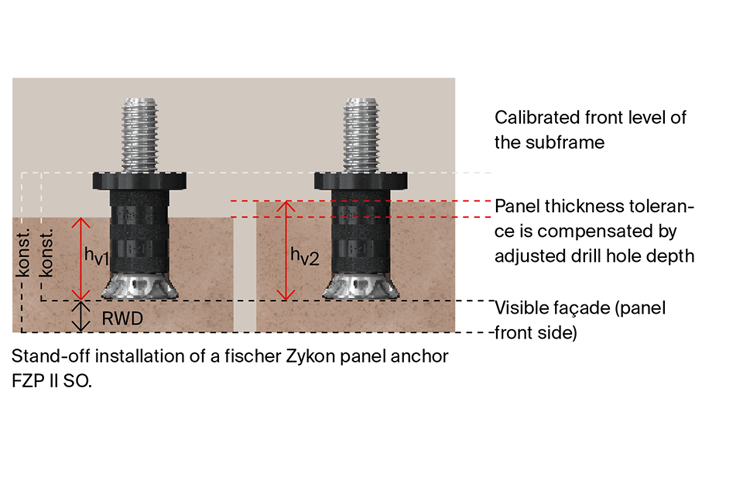

There are two different installation methods for the fischer Zykon panel anchor FZP II:For the flush installation, the installed anchor is flush with the back of the panel. The back of the panel is used as a reference for the constant drill hole depth. This technology is mainly used for fixing reveal panels.

Due to the stand-off installation, the panel thickness tolerances that occur with natural stone panels can be compensated. With this type of installation the constant distance between the bottom of the drill hole and the front side of the panel, the remaining wall thickness (RWD), are used as the reference dimension. As a result, the drill hole depth gets variable. This method also allows the realisation of an element façade as well as factory prefabrication.

The FZP II also proves its worth in situations with the highest demands on the fixing system.Earthquake tests in Shanghai, China, impressively confirmed the outstanding performance of the undercut anchor. The various façade materials mounted with the FZP II withstood accelerations of up to 9.5 m/s2. This corresponds to forces that cause considerable damage and destruction even in modern buildings designed for earthquakes.These results have been confirmed by repeated tests in Italy and France.

The perfectly matching fischer façade systems with the undercut anchors, fitting subframe and advanced drilling technology pays off on the construction site: Installation is simple, fast and independent of the weather. The construction time is shortened - and therefore the costs are also reduced.