Heat, frost, humidity and air pollution - the ravages of time gnaw away at the proudest buildings.

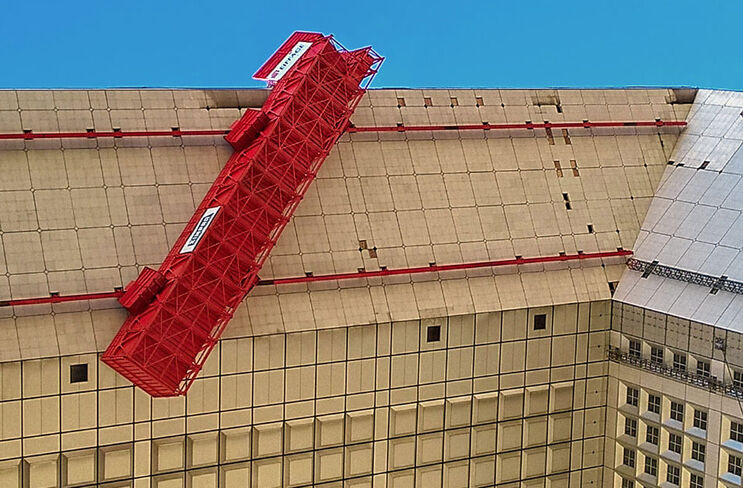

"At the La Grande Arche office tower in Paris, the high wind loads and rain also caused visible signs of wear and soiling on the façade," explains Steven-Henrik Maier, Market Manager France at the fixing specialist fischer SystemTec.

"Deformations, flaking and cracks on the white Carrara marble façade were the result. As a result, those responsible finally decided to renovate the façade in 2015, having already toyed with the idea in 2009."

Since its completion in 1989, the "Grande Arche" has been one of the most popular viewpoints in Paris. No wonder, as the building is located at the end of the approximately eight-kilometre-long visual axis that stretches from the Louvre art museum via the Champs-Élysées and the Arc de Triomphe to the office tower.

The monumental building was designed by Danish architect Johann Otto von Spreckelsen, who wanted the cube-shaped arch to be seen as a "gateway to the world". At around 110 metres high, the 35-storey office tower offers so much space that the Notre-Dame de Paris church, including its crossing tower that collapsed in the major fire on 15 April 2019, would have easily fitted underneath.

When the enquiry came from France in 2015, Steven-Henrik Maier was still in the middle of his studies.

"Basically, the architects in charge wanted a more robust stone that had a similar colour to the white Carrara marble and a form of fixing that was both inconspicuous and secure,"

the now 26-year-old civil engineer summarises the requirements.

Finding the new stone was the minor problem: after a short time, those responsible agreed on the white granite "Bethel White", which is extracted from a quarry in Vermont (USA).

The technical solution of fixing the granite façade panels with undercut anchors from fischer paved the way for the realisation of the project. A fischer project team of six at times took over the coordination of all the international companies involved. "For the west/south construction section (carried out by EDM), for example, we coordinated the timely delivery of the granite in the correct dimensions and thickness with the stone supplier in the USA.

At the same time, we coordinated all the necessary matters with the drilling company in Spain. This ranged from the definition of the drilling rig and drill bits to the drilling drawings and the permissible tolerances," says Market Manager Steven-Henrik Maier, summarising just some of the tasks.

"That's typical fischer," says the 26-year-old, "we take care of everything from the beginning to the end of the project and provide customers and partners with all the necessary information."

The fischer Zykon plate anchors FZP-II are installed from the rear, are not visible in the joint and ensure a form-fit and completely expansion pressure-free fixing in the conically undercut drill hole. Compared to fastenings close to the edge (dowel, plug-in dowel and groove fastenings), this technology achieves lower panel bending moments and higher load-bearing capacities.

In addition, individual panels of a façade can also be easily replaced if necessary. As the differences in colour can be particularly noticeable with natural stone, the French architects Valode & Pistre were happy to make use of this option when renovating "La Grande Arche". And they changed the colour of the slabs as they saw fit.