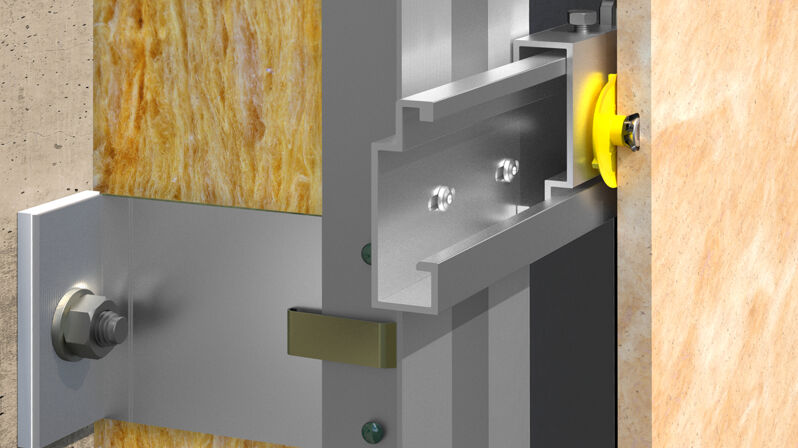

| ETA-approval | |

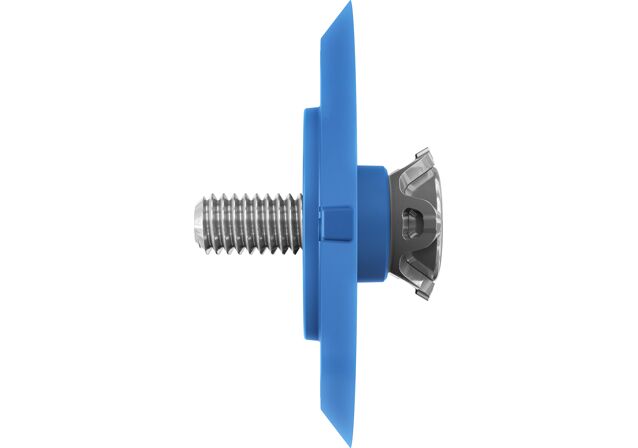

| Min. panel thickness | 11 mm |

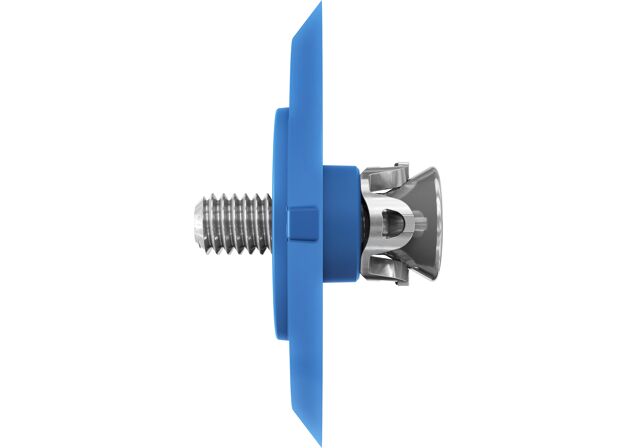

| Embedment depth ( h1 ) | 9 mm |

| Total length ( l ) | 20,5 mm |

| Installed anchor length ( a ) | 11,5 mm |

| Remaining thread length ( b ) | 9 mm |

| Thread ( M ) | M6 |

| Cylindrical diameter ( d0 ) | 11 mm |

| Undercutdiameter ( d1 ) | 13,5 mm |

| Colour washer | blue |

| Seismic-Approval | C1 / C2 |

| System | — |

| Amount | 250 pcs |

| GTIN (EAN-Code) | 4048962217759 |

| BWM | 532646 |