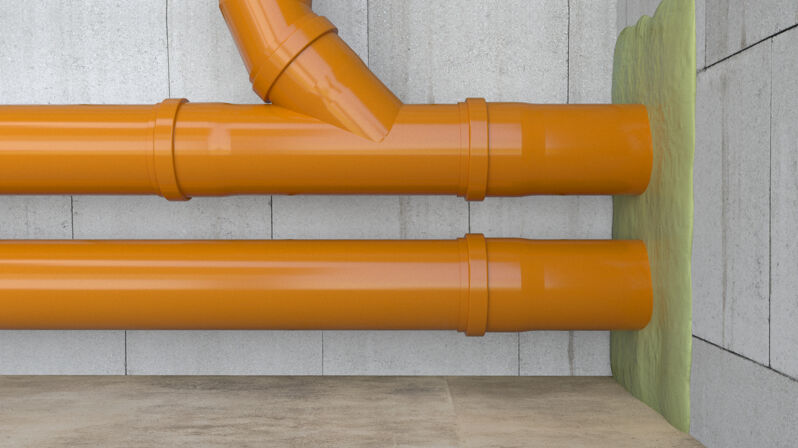

The gun foam with proven resistance to water pressure.

fischer fountain foam PU BS 750 for quick filling of joints between hinged manhole rings as well as sealing and binding well shafts, manhole shafts, and filling in wall penetrations. General building authority test certificate High yield of extruded foam of up to 45 l. External testing of watertightness when used in connection with hinged manhole rings fulfils the requirements for a fountain foam.