Today more than ever, environmental protection is our passion. It is essential to protect the environment, particularly our waterways as they are fundamental to human life and survival. Anchoring for plants containing water polluting substances that are not outfitted with two sealing levels must fulfil specialised requirements in accordance with the German Water Resources Law (WRL, in German WHG) and the regulations on facilities for handling substances that are hazardous to water (AwSV).

The guidelines of the Deutscher Ausschuss für Stahlbeton (DAfStb) “Concrete construction for the handling of water polluting substances” (BUmwS) require the use of bonded anchors that have a usability certificate issued by the building approval authorities. This requirement is ideally fulfilled by a general design certification. fischer has developed and tested a system confirmed as approved for use with existing liquid impermeable concrete (LI/LIP concrete), and has received the first general construction technique permit from the Deutsches Institut für Bautechnik (German technical authority and a serviceprovider for the construction sector DIBt) for a variety of media groups. For coated concrete, fischer has verified through an accredited testing institute and expert report that the fixing system fulfils the WRL. The system also has an ETA for static load, which is a requirement for the design certification.

No matter if LI/LIP concrete or coated concrete: The whitepaper from fischer will answer all key questions regarding WRL compliant anchoring:

Water bodies are an elementary component of the natural balance and serve both as the basis of human life and as a habitat for animals and plants. Therefore potential contamination of water bodies (surface waters and groundwater) must be avoided as a matter of principle. The regulation on facilities for handling substances that are hazardous to water (AwSV) provides concrete specifications for plants handling substances hazardous to water. Summarized briefly, plants such as these must always be designed as a redundant system with a primary and secondary protective barrier.

The “Concrete construction for the handling of water-polluting substances” (BUmwS) guideline by the German Committee for Reinforced Concrete (DAfStb) stipulates that only anchors approved by the building authorities in combination with proof of usability regarding the substance in use may be used for fastenings in concrete sealing surfaces. This is precisely where fischer comes in and offers solutions with which anchorings in WRL sealing surfaces can be carried out safely in accordance with the

WRL and facilities regulation (AwSV). The high-performance injection mortar FIS EM Plus in conjunction with the fischer system components offers the perfect solution for WRL sealing surfaces, both in LP/LIP concrete and in coated WRL surfaces.

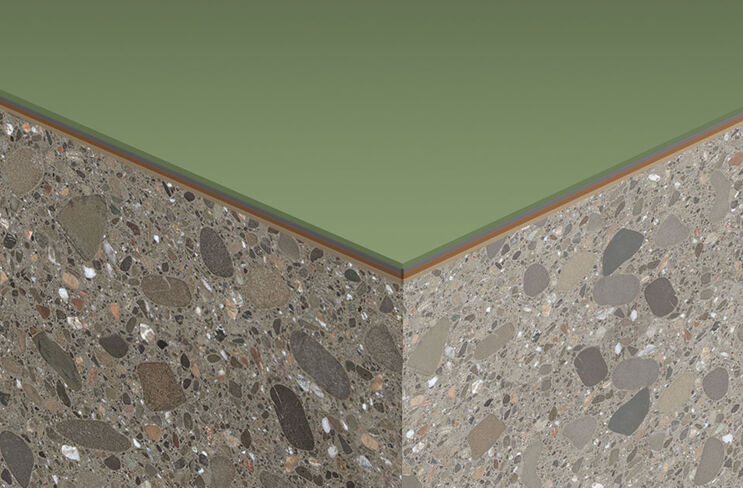

LI/LIP concrete is a type of concrete with special resistance against penetration by water polluting substances. LIP concrete is a liquid impermeable concrete with penetration testing. LI concrete is designed to be considered as liquid impermeable, based on its specialised recipe.

If the WRL surface is created by a coating applied to the concrete, the coating alone is responsible for sealing against substances hazardous to water. Building approvals for the coatings do not include any drill holes, for instance for plugs and anchors, so fischer has developed and tested a system that maintains the seal of the coatings against water polluting substances. fischer has also had this system independently evaluated.

Therefore, fischer has developed a system in which the seal against water polluting substances is retained, even if holes are drilled into the coated concrete.

Tested & officially approved

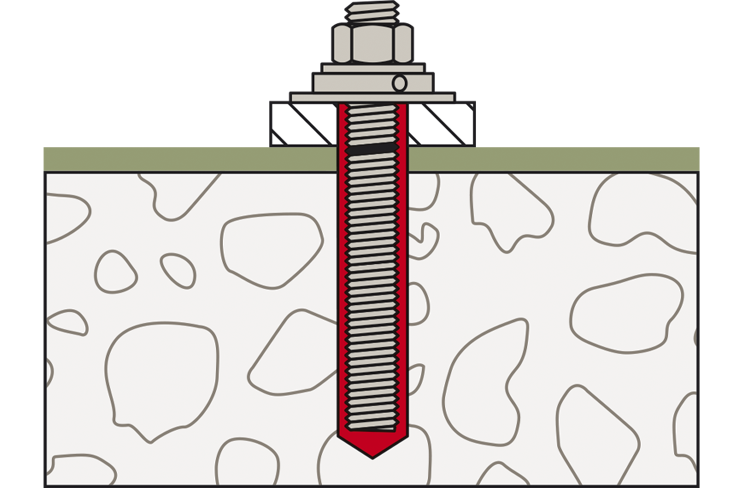

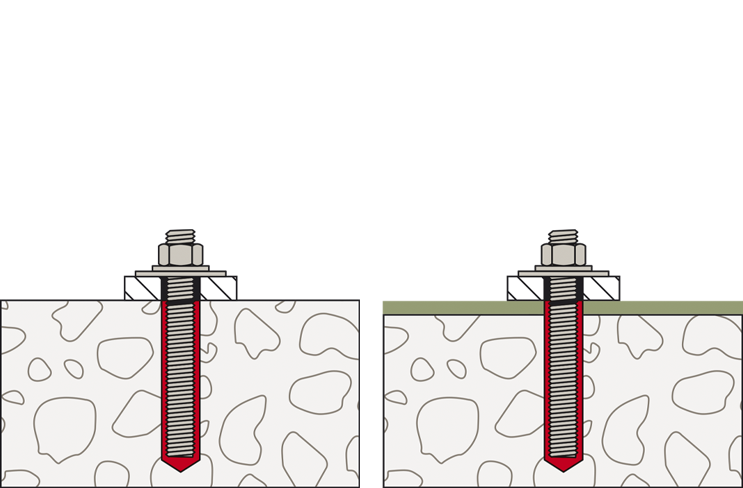

When installing anchors in WRL sealing surfaces, a hole is drilled into the WRL surface, potentially reducing the tightness at this location. However, the tightness and resistance must be verified in the area of the anchors as well.

Now, fischer offers solutions for these applications that can be used to install anchors in WRL sealing surfaces according to the German Water Resources Law (WRL) and facilities regulation (AwSV).

With the injection mortar FIS EM Plus, fischer has obtained the first general design approval for WRL compliant anchoring in liquid-proof concrete (LI-/ LIP concrete). The system was comprehensively tested with materials in media list 4 of the German Institute for Structural Engineering (DIBt).

fischer also has a general construction technique permit for the FIS EM Plus injection mortar for anchorages in coated WHG surfaces with the epoxy resin coating StoCretec WHG System 2. It proves the impermeability and resistance of the FIS EM Plus injection mortar to the media groups listed in the DIBt media list 1. For other epoxy resin coatings, fischer has proven the WRL suitability of the fixing system by an accredited testing institute and an expert report.

The expert report can be provided by a request via the contact form.

With fischer you are on the safe side when anchoring in WRL sealing surfaces!

An anchor according to the WRL must be designed so that no liquid can penetrate through the anchor into the concrete. The drill hole can be constructed using hammer drilling or with a hollow drill bit. In coated concrete, the drill hole can additionally be created using the wet drilling method with diamond drills, whereby the drill must be guided by hand and must not be fixed in the sealing surface.

The drill hole depth must always be at least 50 mm less than the existing component thickness. The epoxy mortar FIS EM Plus, anchor rod FIS A / RG M or internal-threaded anchor RG MI and WRL marking are required. The general construction technique permit requires anchor materials made of stainless steel for WRL application.

The marking disc is an important part of the fischer WRL fixing system. It clearly and permanently indicates use of the correct system, and facilitates simple, reliable building approvals. It is mounted between the washer and attachment.

Optionally, the WRL set can additionally be used for anchorings in coated concrete. The set consists of the WRL marking disc, a filling disc, a rounded washer and an injection adapter and is available in galvanized steel and stainless steel. The WRL set is used to fill and additionally seal the annular gap and to mark the fixing point as a WRL-compliant anchorage.